why CNC Machining Perfrom So Good At Ultirapid?

Ultirapid has built a strong reputation for its superior CNC machining services, delivering high-quality components across various industries. The key to their success lies in a combination of advanced technology, skilled expertise, and a customer-centric approach that ensures excellence at every stage of production. Here's why CNC machining performs so exceptionally well at Ultirapid:

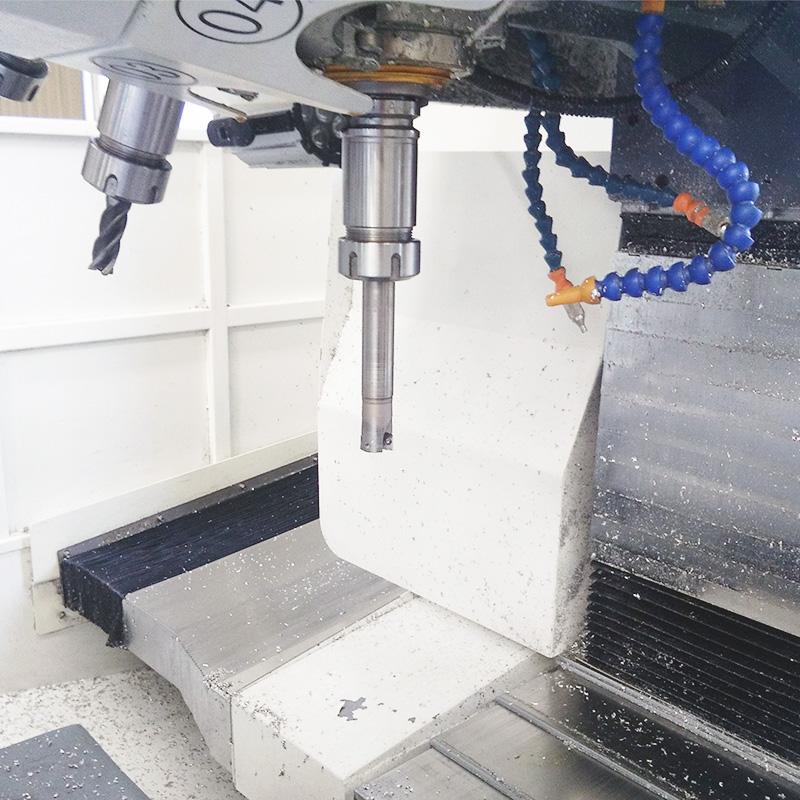

1. Cutting-Edge Technology and Machinery

Ultirapid invests heavily in state-of-the-art CNC machinery. These high-performance machines are equipped with advanced features, such as multi-axis capabilities, which allow for the creation of complex parts with intricate geometries. The precision offered by these machines enables Ultirapid to meet the tightest tolerances, producing components that are consistent, accurate, and reliable.

The ability to process parts on 5-axis CNC machines offers flexibility in designing and manufacturing products. These multi-axis machines allow for the fabrication of parts that would be impossible or highly inefficient with traditional machining methods. Ultirapid continuously upgrades its machinery to stay ahead of the curve, ensuring that their clients benefit from the latest advancements in CNC technology.

2. Expertise and Experience

One of the major reasons CNC machining performs so well at Ultirapid CNC Machining is the team’s expertise. Ultirapid’s engineers and technicians possess years of experience in CNC machining and related fields. They have extensive knowledge of material properties, machine programming, and design principles, which allows them to optimize machining processes for the highest level of efficiency and precision.

Their team also has the skills to troubleshoot potential problems before they arise, ensuring smooth operations and minimal downtime. This expertise, coupled with an understanding of clients' specific needs, allows Ultirapid to deliver custom-tailored solutions across industries like aerospace, automotive, medical devices, and electronics.

3. Precision and Accuracy

Precision is at the heart of CNC machining, and Ultirapid takes this to the next level by adhering to tight tolerances. By utilizing high-precision machinery and meticulous attention to detail, Ultirapid can produce parts with exceptional accuracy, even for the most demanding applications.

This level of precision is crucial in industries such as medical device manufacturing or aerospace, where even the smallest inaccuracies can lead to failures. Ultirapid’s commitment to quality ensures that every component manufactured meets stringent industry standards, leading to durable and reliable end products.

4. Advanced Material Handling

Ultirapid’s CNC machining performs exceptionally well due to its ability to work with a wide variety of materials. Whether it’s metals such as aluminum, steel, titanium, and copper alloys, or advanced plastics like PEEK and ABS, Ultirapid handles each material with the utmost care. Their extensive knowledge of material properties allows for optimized machining, resulting in minimal waste and maximized efficiency.

For example, different materials behave differently under stress, temperature, and during cutting. Ultirapid’s team understands how to adjust machine settings to accommodate these variations, ensuring that the final product is both functional and structurally sound.

5. Fast Turnaround Times

Another factor contributing to the superior performance of CNC machining at Ultirapid is their focus on speed without sacrificing quality. Ultirapid has developed streamlined processes that allow them to go from design to finished part in short time frames. This ability to provide rapid prototyping and quick production runs is essential for clients needing to meet tight deadlines.

By combining advanced software tools, optimized workflows, and efficient machine setups, Ultirapid can significantly reduce lead times. Their fast turnaround capabilities, paired with high-quality output, give businesses the agility they need to succeed in fast-moving industries.

6. Scalability and Flexibility

Ultirapid's CNC machining services are highly scalable. Whether it’s producing a single prototype or scaling up to full production runs, their 5-axis CNC machines are adaptable to any project size. The flexibility to switch between low-volume and high-volume production is a significant advantage, especially for businesses that require prototypes or frequent adjustments to part designs.

The ability to rapidly shift from one production size to another without losing quality is a testament to Ultirapid’s operational efficiency and technical prowess. This adaptability helps businesses manage costs effectively while still receiving high-quality components.

7. Focus on Continuous Improvement

Ultirapid's dedication to continuous improvement also plays a major role in the outstanding performance of their CNC machining services. Their team is always on the lookout for ways to refine processes, adopt new techniques, and implement feedback from clients. This commitment to excellence means that every project is an opportunity to improve and evolve, ensuring that Ultirapid stays at the forefront of the industry.

They also invest in ongoing training and development for their engineers and machinists, ensuring that they stay up to date with the latest machining trends and best practices. This focus on learning and adaptation is critical to maintaining their high standards.

Conclusion

CNC machining performs exceptionally well at Ultirapid CNC Machining due to a combination of advanced technology, a skilled and knowledgeable workforce, and a commitment to precision and efficiency. From handling complex geometries to ensuring fast turnaround times, Ultirapid excels in providing CNC machining services that meet the diverse needs of clients across multiple industries. Their continuous focus on improvement, flexibility, and quality makes them a trusted partner for businesses seeking reliable machining solutions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Travels