Technological Innovations Shaping the Future of Automotive Plastic Compounding

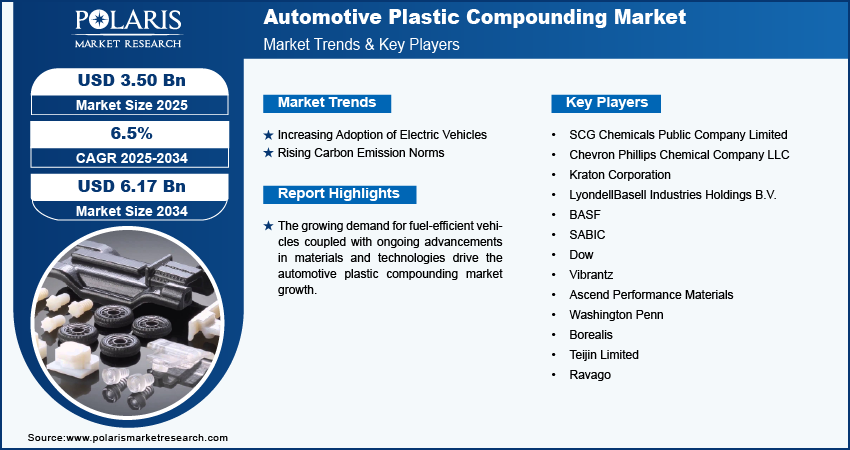

The automotive plastic compounding market size was valued at USD 3.30 billion in 2024. It is projected to grow from USD 3.50 billion in 2025 to USD 6.17 billion by 2034, exhibiting a CAGR of 6.5% during 2025–2034.

Market Overview

Plastic compounding in the automotive industry involves blending polymers with various additives or reinforcements to achieve desired mechanical and thermal properties. This process results in materials that are lighter, more durable, and capable of withstanding harsh operating conditions. The growing emphasis on sustainability and regulatory pressure to meet stringent emission norms worldwide is accelerating the adoption of these engineered materials.

In addition to reducing vehicle weight, polymer compounding provides benefits such as corrosion resistance, enhanced impact strength, and design flexibility, making it a preferred choice for exterior and interior automotive components. The increased use of plastics in electric vehicles (EVs), which require lightweight parts to extend battery range, is another key growth driver.

The market, valued at approximately USD 15 billion in 2024, is forecasted to grow at a compound annual growth rate (CAGR) of around 8% from 2025 to 2035, supported by innovations in compounding technology and expanding automotive production globally.

Market Trends

The automotive plastic compounding market is evolving with several notable trends shaping its trajectory:

- Shift Towards High-Performance Thermoplastics: The transition from traditional plastics to advanced thermoplastic composites enables automotive manufacturers to achieve higher strength-to-weight ratios. These materials offer recyclability and cost-effectiveness, meeting industry demands for sustainability.

- Increasing Use of Reinforced Plastics: Incorporating fillers like glass fiber, carbon fiber, and mineral reinforcements enhances mechanical properties, durability, and thermal stability of compounded plastics, making them suitable for critical automotive parts including under-the-hood components.

- Focus on Sustainable and Bio-Based Polymers: Environmental concerns are encouraging the development and use of bio-based polymers and recycled plastics in automotive compounding, aligning with global sustainability goals and regulatory requirements.

- Growth of Electric Vehicles (EVs) and Hybrid Vehicles: The rising adoption of EVs is propelling demand for lightweight materials to optimize energy consumption. Plastic compounds that provide electrical insulation and thermal management are gaining prominence in EV battery housings and motor components.

- Customization and Functionalization: Advances in polymer chemistry and compounding processes enable the creation of materials with tailored properties such as flame retardancy, UV resistance, and sound absorption, meeting specific automotive application needs.

Country-Wise Analysis

The automotive plastic compounding market presents diverse growth patterns across key countries, influenced by regional automotive production, regulatory frameworks, and technological advancements.

United States

The U.S. market is expanding steadily, driven by high demand for lightweight vehicles to comply with Corporate Average Fuel Economy (CAFE) standards. Increasing investments in electric and autonomous vehicles foster adoption of specialized plastic compounds. The focus on sustainability encourages use of recycled materials in compounding. Additionally, the automotive aftermarket for replacement parts also contributes to growth.

Germany

Germany, home to some of the world’s leading automotive manufacturers, exhibits robust demand for advanced plastic compounding solutions. Strict European Union regulations on emissions and vehicle safety drive innovation in reinforced plastics and thermoplastic composites. The country’s focus on precision engineering promotes high-performance polymer use in luxury and commercial vehicles.

China

China stands as the largest automotive market globally and plays a pivotal role in the plastic compounding segment. Government incentives promoting electric vehicle adoption and investments in domestic automotive manufacturing fuel market growth. The rising middle class and increasing urbanization boost demand for passenger cars equipped with lightweight plastic components. Local innovation in polymer compounding is also gaining traction.

Read More @ https://www.polarismarketresearch.com/industry-analysis/automotive-plastic-compounding-market

Japan

Japan’s automotive plastic compounding market benefits from the country’s leadership in hybrid and electric vehicle production. Stringent emission regulations and a strong focus on fuel efficiency compel manufacturers to integrate automotive lightweight materials extensively. Japan is also advancing the development of bio-based polymers and recycling technologies for compounding.

India

India’s growing automotive industry, marked by rising production of two-wheelers, passenger vehicles, and commercial vehicles, is driving demand for plastic compounding materials. Government policies supporting electric mobility and infrastructure development contribute to market expansion. The country is increasingly adopting advanced polymer compounding techniques to meet local and export market requirements.

South Korea

South Korea’s automotive plastic compounding market is influenced by the country’s strong presence in electric and autonomous vehicle manufacturing. Innovations in thermoplastic composites to improve vehicle safety and reduce weight are prominent. South Korean regulatory bodies emphasize environmental compliance, encouraging the use of sustainable plastics.

Brazil

Brazil’s automotive sector recovery is supporting increased use of compounded plastics in vehicle manufacturing and aftermarket parts. The demand for lightweight, corrosion-resistant materials to enhance fuel efficiency aligns with global trends. However, economic fluctuations and import tariffs pose challenges, moderating growth.

Mexico

As a key automotive manufacturing hub for North America, Mexico shows steady growth in plastic compounding demand. The North American Free Trade Agreement (USMCA) promotes automotive exports, encouraging manufacturers to optimize material costs through advanced compounding. The market benefits from proximity to the U.S. and growing adoption of EV technology.

France

France’s automotive market is evolving with increased emphasis on environmental regulations and electric vehicle adoption. The country supports innovation in reinforced plastics and recyclable materials for compounding. Growing investment in light commercial vehicles also expands application areas for plastic compounds.

Conclusion

The Automotive Plastic Compounding Market is set for transformative growth driven by innovations in thermoplastic composites, reinforced plastics, and sustainable polymer compounding solutions. Regional markets reflect varying growth dynamics influenced by local automotive industry trends, government policies, and technological adoption.

As the global automotive landscape shifts towards electrification, lightweight design, and sustainability, plastic compounding will remain a critical enabler for manufacturers striving to meet performance, cost, and environmental objectives.

More Trending Latest Reports By Polaris Market Research:

Personal Protective Equipment (PPE) Market

Diamond Cutting And Polishing Market

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Travels