Understanding the Application of Adjustable Fixtures in CNC Machining

Adjustable fixtures are revolutionizing CNC machining by addressing the limitations of dedicated fixtures. This article explores the types of adjustable fixtures—standardized, group, and combination—and highlights their benefits in enhancing flexibility and efficiency in manufacturing.

1. Introduction

In CNC machining, traditional fixtures often work well for specific tasks but fall short when it comes to versatility. To tackle this issue, adjustable fixtures are becoming increasingly popular. They offer a flexible solution for various workpieces and operations.

2. Standardized Fixtures

Standardized fixtures are built from standardized components, making them highly efficient for production. Key parts like the fixture base, locating elements, and clamping systems are pre-defined, allowing for easier sourcing and assembly. This streamlines both design and manufacturing processes, reducing costs and speeding up production. Moreover, when new products are developed, these fixtures can be disassembled and reused, maximizing their lifespan.

3. Group Fixtures

In workshops focused on small-batch, diverse production, group fixtures are essential. They allow for parts to be organized based on shared characteristics, enabling the use of the same machinery and tooling. For instance, parts like shafts, sleeves, gears, and brackets can be grouped together. With minimal adjustments to the locating and clamping components, manufacturers can switch from processing one part to another seamlessly.

4. Combination Fixtures

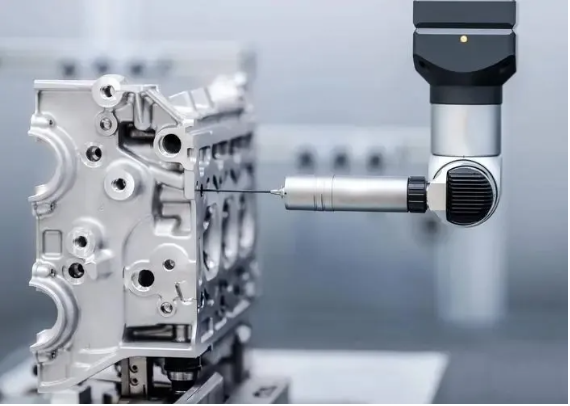

Combination fixtures consist of a set of standardized parts that come in various shapes and sizes, all designed for interchangeability and durability. These components can be assembled into fixtures for different machines, such as lathes, milling machines, and drill presses, based on the specific needs of the workpiece. After use, these fixtures can be easily disassembled, cleaned, and stored for future tasks, making them a modern solution in machining.

5. Universal Adjustable Fixtures

For parts that share similar characteristics, universal adjustable fixtures can be a perfect fit. When considering these fixtures, it's essential to analyze several factors: – Structural Similarity: Look for similarities in processing surfaces, locations, procedures, and technical requirements, especially the positioning references. – Functional Compatibility: Assess whether similar clamping and locating methods can be employed. – Dimensional Similarity: Ensure that the dimensions and positioning references are close enough to allow for efficient use of the adjustable fixture.

6. Conclusion

Fixtures are crucial tools in CNC machining, playing a significant role in enhancing production efficiency. As the machinery industry evolves, the development and innovation of these fixtures remain a key focus for machinists and engineers. Embracing adjustable fixtures can lead to significant improvements in flexibility and cost-effectiveness in manufacturing processes.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Travels