High-Performance Elastomers: Technological Evolution in Silicone Compounds

Silicone elastomers are a class of synthetic materials known for their exceptional thermal stability, chemical resistance, flexibility, and biocompatibility. These versatile polymers are widely used in applications ranging from automotive gaskets and seals to medical implants and electronic encapsulants. Their unique molecular structure allows them to maintain performance characteristics under extreme temperatures and stress, making them a preferred choice for industries that demand durability and safety.

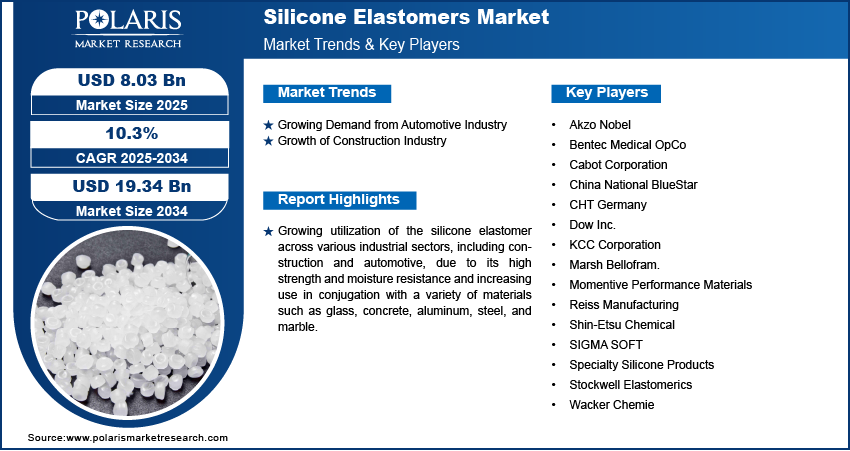

The global silicone elastomers market size was valued at USD 7.29 billion in 2024. It is projected to grow from USD 8.03 billion in 2025 to USD 19.34 billion by 2034, exhibiting a CAGR of 10.3% during 2025–2034.

Furthermore, the market is benefiting from the shift toward electric vehicles, which require durable insulating materials for battery protection and thermal management. Alongside this, the demand for aesthetically appealing, soft-touch materials in consumer electronics is also pushing manufacturers to innovate and expand their silicone elastomer portfolios.

Market Segmentation

The silicone elastomers market is segmented based on product type, process, and end-use industry.

By Product Type:

- High-Temperature Vulcanized (HTV) Silicone Elastomers

- Known for their strength and heat resistance, HTV silicones are primarily used in automotive, aerospace, and industrial applications.

- These are used in sealants, adhesives, and coatings, particularly in construction and electronics.

- A rapidly growing segment due to its suitability for injection molding and use in medical devices, wearables, and electrical components.

By Process:

- Injection Molding

- Compression Molding

- Extrusion

Injection molding dominates due to its compatibility with high-volume, precision applications such as medical equipment and automotive parts.

By End-Use Industry:

- Automotive

- Used in gaskets, spark plug boots, and sensor covers.

- Medical-grade silicones are used in catheters, tubing, respiratory masks, and implantable devices.

- Used in insulating coatings, keypads, and sealing components.

- Includes kitchenware, toys, and wearable devices.

- Silicone sealants are key materials in weatherproofing and structural glazing.

The healthcare and automotive segments are expected to be the fastest-growing applications due to increased safety standards and performance requirements.

Regional Analysis

North America

North America holds a significant share of the silicone elastomers market, driven by well-established automotive and healthcare sectors. The U.S. is at the forefront of innovation in silicone-based materials, with high R&D investments and a strong manufacturing base. The growing use of silicone elastomers in electric vehicles and wearable medical devices is creating new growth avenues.

Furthermore, the FDA’s regulatory approval of various silicone-based medical products has increased confidence in their safety and biocompatibility, fueling further adoption.

Read More @ https://www.polarismarketresearch.com/industry-analysis/silicone-elastomers-market

Europe

Europe is a mature market with a strong presence in automotive and aerospace manufacturing. Germany, France, and the UK are key contributors, with demand rising for high-temperature vulcanized silicone in under-the-hood automotive components. The region is also emphasizing sustainability and energy efficiency, leading to the use of advanced silicone elastomers in green building construction and renewable energy applications.

The European healthcare industry is also integrating medical-grade silicones in diagnostic and therapeutic devices, contributing to steady market growth.

Asia-Pacific

Asia-Pacific is the fastest-growing regional market, driven by rapid industrialization, urbanization, and a burgeoning middle class. China, Japan, India, and South Korea are major contributors. The growth of the automotive and electronics industries in China and Japan is creating substantial demand for durable and high-performance elastomers.

India’s booming medical device manufacturing sector is also increasingly utilizing liquid silicone rubber for applications in prosthetics, surgical tools, and diagnostic equipment. The rise in healthcare spending and improvements in healthcare infrastructure are expected to further fuel demand in the region.

Latin America

Latin America, led by Brazil and Mexico, is showing positive market momentum. Silicone elastomers are being increasingly adopted in the construction and automotive industries due to their weatherability and long service life. Expansion in infrastructure and the growing emphasis on quality healthcare are expected to support long-term market growth.

Middle East & Africa

The Middle East and Africa region is gradually emerging as a growth hub due to increased investments in healthcare and construction. The region’s harsh climatic conditions make silicone elastomers ideal for outdoor sealing and insulating applications. The adoption of silicone materials in oil & gas and solar energy projects is also gaining pace.

Key Companies

Several leading players are actively shaping the silicone elastomers market through technological innovations, mergers and acquisitions, and regional expansions. These companies are focusing on expanding production capacity, enhancing product quality, and developing specialized grades of elastomers to cater to evolving end-user needs.

Key companies in the global silicone elastomers market include:

- Dow Inc.

- Wacker Chemie AG

- Momentive Performance Materials Inc.

- Shin-Etsu Chemical Co., Ltd.

- Elkem ASA

- KCC Corporation

- Reiss Manufacturing Inc.

- Specialty Silicone Products Inc.

- Nusil Technology LLC

- Primasil Silicones Ltd.

These companies offer a wide range of silicone elastomer products, including high-purity medical-grade silicones, flame-retardant grades, and elastomers suitable for extreme environments. Many are investing in sustainable production technologies and bio-based alternatives to meet rising environmental regulations and consumer expectations.

Partnerships with OEMs and healthcare device manufacturers are also a key strategy among these players to secure long-term supply contracts and co-develop new applications.

Future Outlook

The silicone elastomers market is poised for sustained growth, bolstered by a convergence of innovation, regulatory support, and rising consumer demand across diverse industries. The ongoing shift toward miniaturized electronics, advanced healthcare solutions, and electric mobility is expected to drive the development of next-generation silicone-based materials.

With increasing investments in R&D and a growing focus on sustainability, the industry is expected to witness the introduction of more eco-friendly and high-performance products in the coming years.

As manufacturers continue to explore new application frontiers—ranging from wearable health monitors to lightweight aerospace components—the versatility and durability of silicone elastomers will ensure their integral role in shaping future technologies.

More Trending Latest Reports By Polaris Market Research:

Activated Bleaching Earth Market

Active Calcium Silicate Market

Advanced Carbon Materials Market

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Travels