Robotic Paint Boot Market Sees Surge in Automated Paint System Demand

Robotic Paint Boot Market grows with strict safety rules, rising demand for hazard control, and adoption of automated painting in automotive and aerospace sectors.

According to a recent report by TechSci Research titled “Robotic Paint Booth Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2030F”, the Global Robotic Paint Booth Market was valued at USD 3.56 billion in 2024 and is projected to grow to USD 6.42 billion by 2030, at a robust compound annual growth rate (CAGR) of 10.17%. This growth is underpinned by increasing demand for automation, stringent environmental regulations, and the expanding adoption of smart manufacturing technologies across multiple industries—most notably in the automotive sector.

Efficiency and Precision Drive Market Growth

Traditional manual painting methods are gradually being phased out due to several inherent inefficiencies, including high volatile organic compound (VOC) emissions, excessive paint wastage, and inconsistent application quality. These drawbacks not only raise environmental and safety concerns but also lead to higher operational costs and product rework. In contrast, robotic paint booths offer a highly efficient alternative by delivering precision painting with minimal waste.

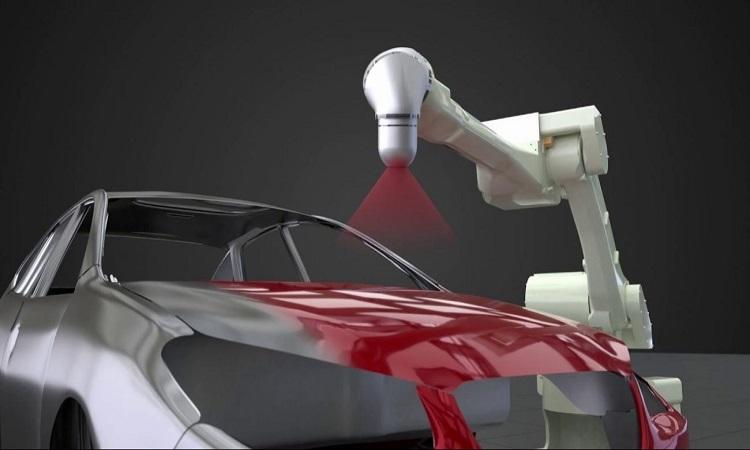

Advanced robotic paint booths are engineered with sophisticated sensors, AI-powered programming, and machine learning algorithms that enable consistent and uniform paint application. These systems significantly reduce overspray and can cut paint usage by up to 30%, leading to notable cost savings. Moreover, they reduce operator exposure to hazardous chemicals and eliminate fatigue-related errors that are common in manual processes. These benefits make robotic paint booths a compelling choice for manufacturers aiming to boost productivity, enhance safety, and achieve greater process control.

Automotive Industry Remains a Dominant End-User

By end-user segmentation, the automotive industry held the largest share of the robotic paint booth market in 2024, and it continues to be the primary driver of global demand. With the ongoing evolution of vehicle design, rising customer expectations, and the surge in electric vehicle (EV) production, automotive manufacturers are increasingly turning to automation to stay competitive. Robotic painting systems offer the speed, accuracy, and repeatability needed to meet high-volume production demands without compromising on finish quality.

These systems ensure smooth and uniform application of primers, base coats, and topcoats, reducing human error and ensuring compliance with environmental regulations. In addition, robotic paint booths are instrumental in helping automotive companies reduce VOC emissions, contributing to sustainability goals and regulatory compliance.

The broader shift toward Industry 4.0 and digital transformation is also influencing market dynamics. Automotive OEMs are investing in AI-driven paint booths capable of real-time process monitoring, predictive maintenance, and dynamic control of paint thickness and flow. Companies such as Tesla, BMW, Ford, and Toyota are leading the way, integrating robotic painting solutions across their production lines to improve throughput, reduce waste, and enhance vehicle aesthetics.

Furthermore, the rapid growth in EV manufacturing is contributing to the increased use of robotic paint booths. EV manufacturers are keen on leveraging high-precision paint systems to create distinctive, high-quality finishes that appeal to environmentally conscious consumers. These systems support customized coatings, metallic finishes, and multi-tone applications that are often required in premium EV models.

Technological Advancements and Innovations

The robotic paint booth market is benefiting from a wave of technological innovations. The integration of collaborative robots (cobots) has broadened the application scope, enabling safer and more flexible operations in environments where human-robot interaction is essential. Cobots are particularly effective in handling complex geometries, multi-material surfaces, and high-detail finishing work, enhancing the adaptability of robotic paint systems.

Other notable advancements include the adoption of electrostatic spray technology, 3D vision-guided systems, and automated color matching tools. These innovations are streamlining the painting process, improving accuracy, and minimizing paint consumption. Additionally, modular robotic paint booths equipped with self-cleaning mechanisms and automatic nozzle adjustments are improving uptime and reducing maintenance costs.

As sustainability becomes a central theme in manufacturing, robotic paint booths are also being engineered to align with circular economy principles. Recyclable filters, energy-efficient air handling systems, and low-emission spray techniques are being integrated to minimize the environmental footprint of industrial painting operations.

Browse over XX Market data Figures spread through XX Pages and an in-depth TOC on the "Global Robotic Paint Booth Market.”

https://www.techsciresearch.com/report/robotic-paint-booth-market/28247.html

Asia-Pacific Emerges as a High-Growth Region

Regionally, the Asia-Pacific region is anticipated to be the fastest-growing market for robotic paint booths during the forecast period. Countries such as China, India, Japan, and South Korea are witnessing substantial growth in automotive manufacturing, supported by robust domestic demand, growing exports, and government-backed industrial development initiatives.

China, in particular, is at the forefront of the regional expansion, with aggressive investments in electric vehicles, robotics, and smart factory technologies. The rising adoption of automation to improve quality and reduce reliance on manual labor is fueling demand for robotic paint booths. Similarly, India is rapidly modernizing its manufacturing capabilities, with increasing interest in robotic solutions to meet global quality standards and export competitiveness.

Government initiatives aimed at promoting sustainable manufacturing and industrial automation—such as Japan’s Society 5.0 and South Korea’s Manufacturing Innovation Strategy—are further encouraging the adoption of robotic paint booths. The region's cost-competitive labor market, combined with growing technological capabilities, positions Asia-Pacific as a key hub for future growth in this sector.

Conclusion

The Global Robotic Paint Booth Market is poised for substantial expansion through 2030, driven by growing demand for operational efficiency, enhanced product quality, and reduced environmental impact. As industries continue to modernize their production lines, robotic paint booths offer a powerful solution for automated, precise, and eco-friendly painting applications. With continued innovation and rising adoption across sectors—especially in automotive manufacturing—the market is set to play a critical role in the future of industrial automation.

Major companies operating in the Global Robotic Paint Booth Market are:

ABB Ltd.

Yaskawa Electric Corporation

Effort Intelligence Equipment Co. Ltd.

Staubli International AG

Kawasaki Heavy Industry Co. Ltd.

Fanuc Corporation

KUKA AG

SAIMA Meccanica S.p.A.

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=28247

Customers can also request 10% free customization in this report.

“The Global Robotic Paint Booth Market is expected to rise in the upcoming years and register a significant CAGR during the forecast period. The Robotic Paint Booth Market is poised for substantial expansion, driven by advancements in automation, AI-powered robotics, and smart manufacturing technologies. The rising demand for electric vehicles (EVs) is accelerating the need for high-precision, environmentally sustainable painting solutions, creating new growth avenues. Additionally, expanding automotive production in emerging markets, particularly across Asia-Pacific, presents lucrative investment opportunities for manufacturers seeking cost-efficient, high-speed robotic systems.

Furthermore, technological innovations, including electrostatic painting, automated color matching, and AI-driven quality control, are enhancing operational efficiency while minimizing paint waste and VOC emissions, aligning with regulatory mandates and sustainability objectives, thus fostering broader market adoption. Therefore, the Market of Robotic Paint Booth is expected to boost in the upcoming years.,” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based global management consulting firm.

“Robotic Paint Booth Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented, By Type (Explosion Proof Type and Non-Explosion Proof Type), By Application (Paint Booth and Paint Booth Robots), By End-User (Automotive and Non-automotive), By Region & Competition, 2020-2030F”, has evaluated the future growth potential of Global Robotic Paint Booth Market and provides statistics & information on the Market size, structure, and future Market growth. The report intends to provide cutting-edge Market intelligence and help decision-makers make sound investment decisions., The report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the Global Robotic Paint Booth Market.

Contact

Techsci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

Tel: +13322586602

Email: sales@techsciresearch.com

Website: www.techsciresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Travels