Intrinsically Safe Equipment Industry Outlook: Regulatory Impact and Market Drivers

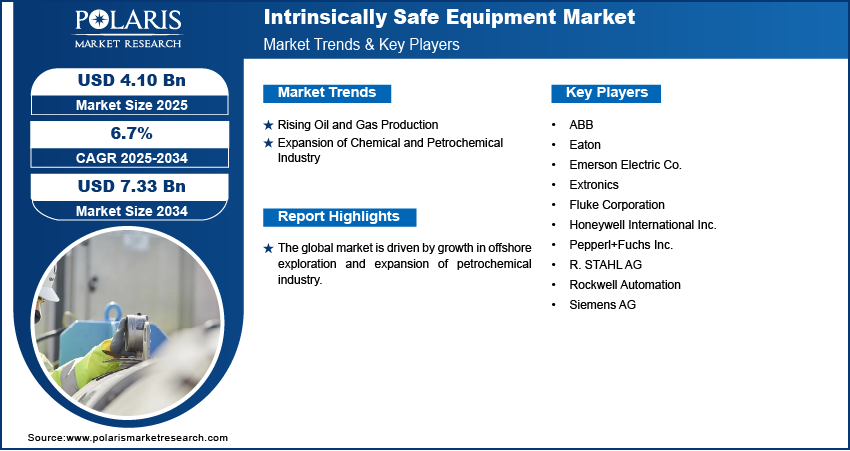

The global Intrinsically Safe Equipment Market is experiencing significant expansion driven by stringent safety regulations, rising industrial automation, and heightened awareness regarding hazardous area safety. As industries such as oil & gas, mining, chemicals, pharmaceuticals, and manufacturing continue to prioritize workplace safety, intrinsically safe equipment is becoming essential to prevent accidents in environments prone to explosions and fires.

The global intrinsically safe equipment market size was valued at USD 3.85 billion in 2024, growing at a CAGR of 6.7% during 2025–2034.

Market Overview

Intrinsically safe equipment refers to devices designed and certified to operate safely in explosive atmospheres by limiting energy, both electrical and thermal, to prevent ignition. These safety measures are crucial in hazardous zones where flammable gases, vapors, or dust are present.

The market growth is propelled by increasing adoption of explosion-proof certification standards, evolving safety compliance requirements, and integration of intrinsically safe technology in industrial automation systems. This equipment includes intrinsically safe sensors, communication devices, lighting, switches, and control systems designed to meet rigorous safety protocols.

The escalating focus on reducing operational hazards and ensuring uninterrupted processes in hazardous environments has reinforced the need for reliable intrinsically safe solutions, expanding their application scope globally.

Key Market Trends

- Stringent Safety Compliance and Regulatory Enforcement

Governments and regulatory bodies worldwide are enforcing stricter safety compliance standards for equipment used in hazardous areas. Compliance with certifications such as ATEX (Europe), IECEx (International), and NEC/CEC (North America) is becoming mandatory, propelling demand for intrinsically safe devices. - Integration with Industrial Automation and IoT

As industries adopt smart manufacturing and industrial automation practices, intrinsically safe equipment is increasingly integrated with wireless communication, sensors, and control systems to enhance operational safety without compromising efficiency. - Technological Advancements in Explosion-Proof Certification

Continuous improvements in design, materials, and testing methodologies are advancing explosion-proof certification capabilities, allowing intrinsically safe equipment to operate reliably in increasingly challenging environments. - Expansion in Emerging Economies

Rapid industrialization and infrastructure development in Asia-Pacific, Latin America, and the Middle East are driving increased deployment of intrinsically safe equipment, particularly in oil & gas, mining, and chemical processing sectors.

Read More @ https://www.polarismarketresearch.com/industry-analysis/intrinsically-safe-equipment-market

Country-Wise Market Analysis

United States

The United States is a major market for intrinsically safe equipment, supported by extensive oil & gas, chemical, and mining industries. Strict enforcement of safety regulations by OSHA and other agencies mandates the use of certified intrinsically safe devices in hazardous environments.

The country is witnessing increased integration of intrinsically safe technology with digital solutions and industrial automation platforms to boost productivity while ensuring hazardous area safety. Additionally, growing investments in renewable energy and petrochemical expansions are sustaining market growth.

Germany

Germany, as a leading industrial hub in Europe, enforces rigorous safety compliance regulations in line with ATEX directives. The country’s automotive, chemical, and manufacturing sectors are adopting intrinsically safe equipment to meet these standards and ensure operational continuity.

Germany’s focus on Industry 4.0 drives the incorporation of intrinsically safe sensors and control systems in automated production lines, enhancing both safety and efficiency. Innovations aimed at enhancing explosion-proof certification processes further strengthen the market.

China

China’s booming industrial sector, particularly in oil & gas, mining, and chemical processing, is a significant driver of the intrinsically safe equipment market. Government emphasis on workplace safety and environmental protection has heightened regulatory scrutiny, fostering demand for certified safety equipment.

The surge in industrial automation within Chinese manufacturing plants is fueling the integration of intrinsically safe devices with IoT and wireless networks to facilitate real-time monitoring and hazard prevention. Domestic production capabilities of such equipment are also improving to meet expanding market requirements.

United Kingdom

The UK market emphasizes strict compliance with ATEX and IECEx standards, driven by its mature oil & gas and chemical industries. Intrinsically safe equipment is essential for maintaining safety and minimizing downtime in offshore drilling and refining operations.

Additionally, the UK’s growing pharmaceutical and food processing industries are adopting intrinsically safe solutions to comply with stringent safety protocols and quality standards. The ongoing digitization of industrial processes encourages increased use of smart intrinsically safe devices.

India

India’s rapid industrialization and infrastructure projects in sectors like oil & gas, petrochemicals, and mining are catalyzing demand for intrinsically safe equipment. Government initiatives to enhance workplace safety and stricter enforcement of safety laws are raising market prospects.

India’s expanding adoption of industrial automation and digital safety management systems supports increased utilization of intrinsically safe sensors, communication tools, and control devices designed for hazardous environments. The country is also witnessing growth in local manufacturing of certified safety equipment.

Canada

Canada’s mining and oil & gas industries are the primary drivers of the intrinsically safe equipment market. Compliance with NEC and CSA standards ensures widespread adoption of intrinsically safe solutions to protect workers and infrastructure.

The market is further boosted by investments in upgrading aging industrial plants with modern safety equipment that integrates with automated control systems. Emphasis on hazardous area safety in remote and harsh environments continues to fuel demand.

Australia

Australia, with its vast mining and energy sectors, remains a key market for intrinsically safe equipment. Government regulations, combined with industry best practices, ensure rigorous safety compliance in equipment selection.

The increasing incorporation of intrinsically safe wireless sensors and monitoring systems within mining operations and energy infrastructure reflects a shift towards smart safety management supported by industrial automation.

Brazil

Brazil’s expanding oil & gas exploration and chemical manufacturing sectors are driving the market for intrinsically safe equipment. Enhanced focus on occupational health and safety regulations is promoting the adoption of explosion-proof certified devices.

The market is growing alongside investments in infrastructure and automation technologies that require reliable intrinsically safe systems to prevent ignition risks in hazardous environments.

Conclusion

The global Intrinsically Safe Equipment Market is poised for substantial growth fueled by the increasing emphasis on hazardous area safety, evolving safety compliance regulations, and the integration of intrinsically safe solutions within industrial automation frameworks. Countries with mature industrial sectors, such as the United States, Germany, and the UK, maintain strong demand through rigorous regulatory enforcement and technological innovation in explosion-proof certification.

Meanwhile, emerging economies like China, India, and Brazil are rapidly expanding their adoption of intrinsically safe equipment driven by industrial growth and modernization initiatives. Australia and Canada continue to leverage these technologies for enhanced safety in mining and energy sectors.

More Trending Latest Reports By Polaris Market Research:

Advanced Carbon Materials Market

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Travels